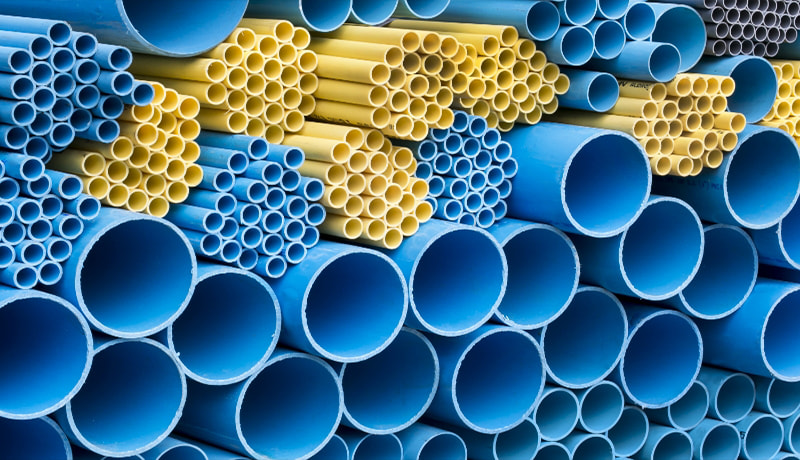

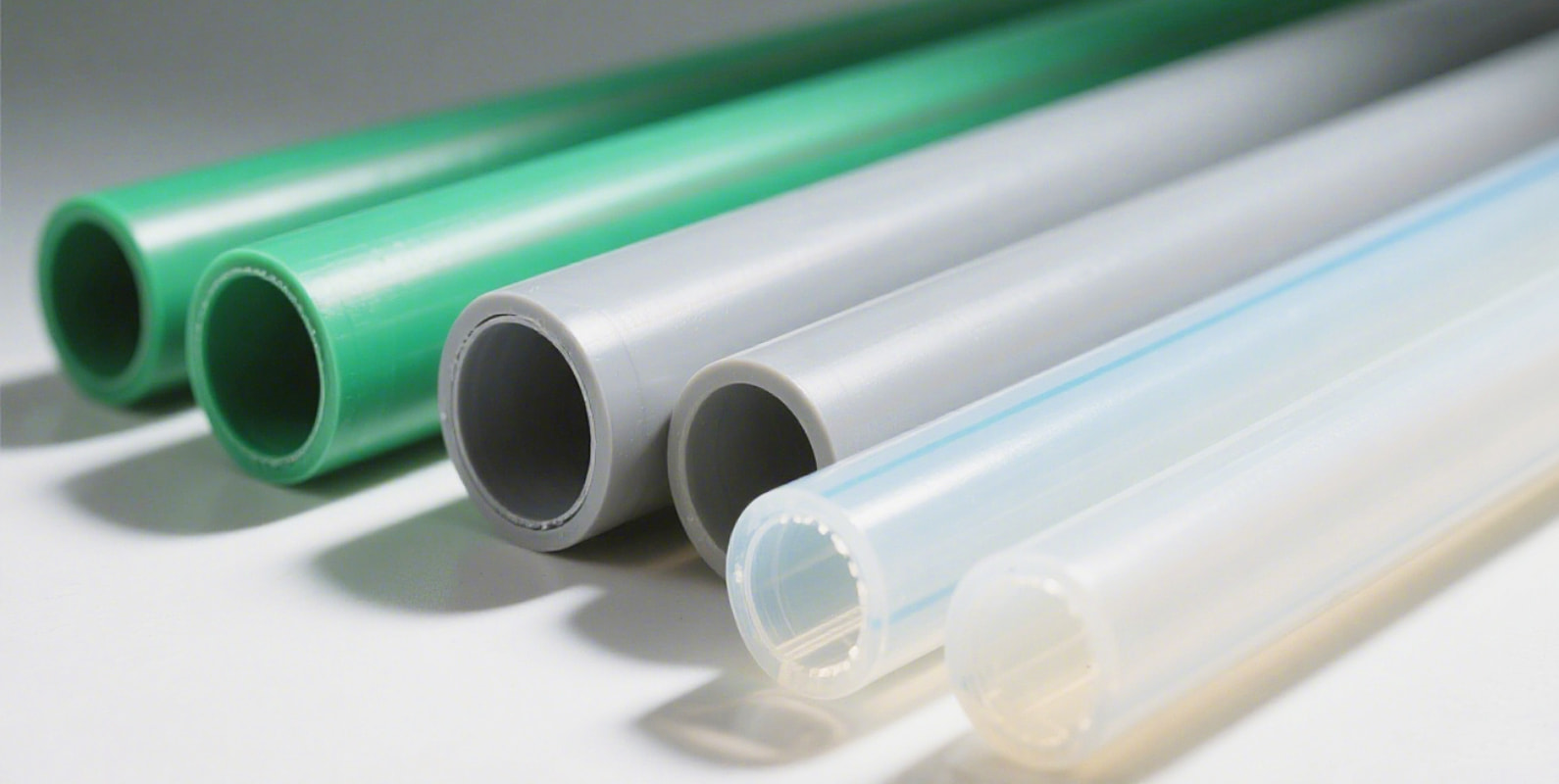

Construction Pipes

In every successful construction project, piping systems serve as the silent backbone of a building’s vital infrastructure. Manufactured with precision from durable materials, these pipes are built to withstand high pressure, bad temperatures, and harsh environmental conditions. Their strength, flexibility, and long service life make them indispensable in both residential and commercial developments. A key advantage lies in their adaptability—whether for water supply, drainage, gas transmission, electrical conduits, or HVAC systems, building pipes are engineered to meet diverse needs with safe and reliable performance. Seamless connection systems significantly reduce the risk of leakage, while lightweight construction enhances transport efficiency and simplifies installation, effectively cutting labor time and overall costs. From underground sewage networks to vertical riser systems in high-rise buildings, construction piping ensures smooth media flow and structural integrity. In urban planning and infrastructure, they form hidden yet essential pathways, supporting sanitation, clean water delivery, and energy efficiency. Choosing construction-grade piping means choosing a low-maintenance, highly reliable engineering safeguard—empowering developers, engineers, and owners with long-term peace of mind. With precise material selection and integrated system performance, these pipelines synchronize with structural elements to breathe life into durable, future-ready architecture.

中文简体

中文简体 English

English