New Building Materials

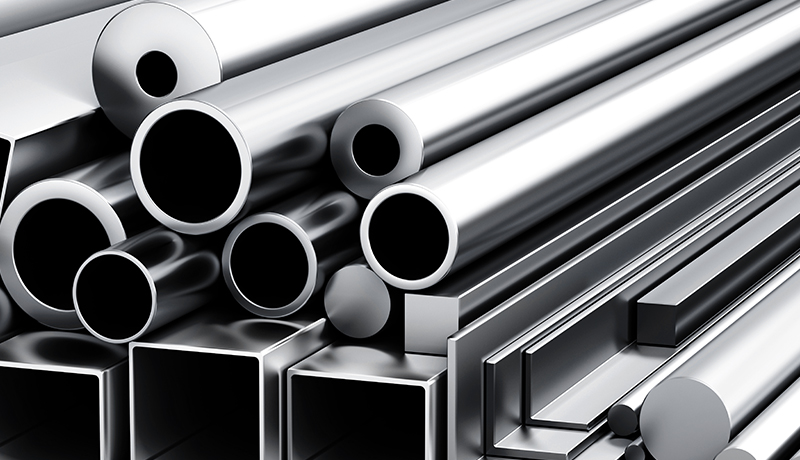

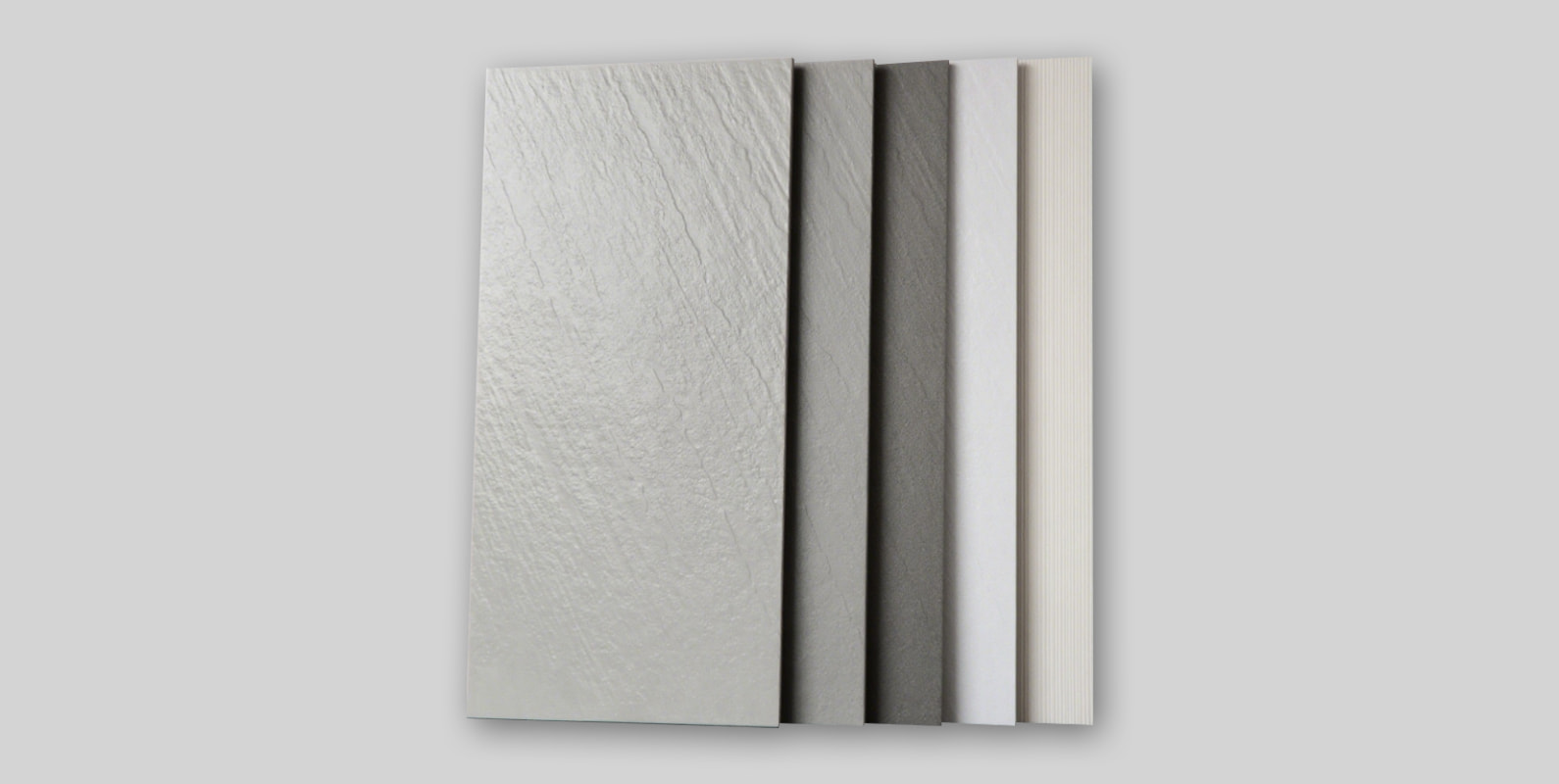

Structural steel and decorative materials represent two complementary material systems within the construction industry. Structural steel—typically in the form of rebar, steel sections, and plates—serves as the backbone of buildings, providing critical load-bearing and stabilizing functions for beams, columns, and frames. Its strength, toughness, and mechanical performance are essential for ensuring structural safety, and it adheres strictly to technical standards set by the metallurgical industry for strength and durability. In contrast, architectural decoration materials focus on enhancing surface aesthetics and expanding functionality. This category includes tiles, coatings, panels, and glass, which shape spatial style and visual appeal through color, texture, and material finish, while also offering practical features such as waterproofing, fire resistance, and sound insulation. These materials span industries including construction, chemicals, and surface engineering, with an emphasis on decorative value, environmental friendliness, and installation adaptability. While structural and decorative materials traditionally serve distinct roles, emerging architectural trends are fostering their integration. Innovations such as high-strength, corrosion-resistant steels and eco-friendly, intelligent decorative materials are collectively advancing the industry toward safer, more aesthetically pleasing, and sustainable building practices.

中文简体

中文简体 English

English