Wires and Cables

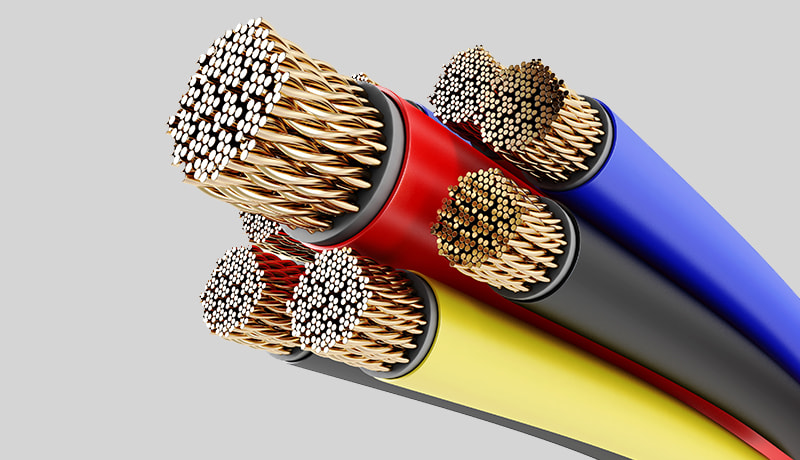

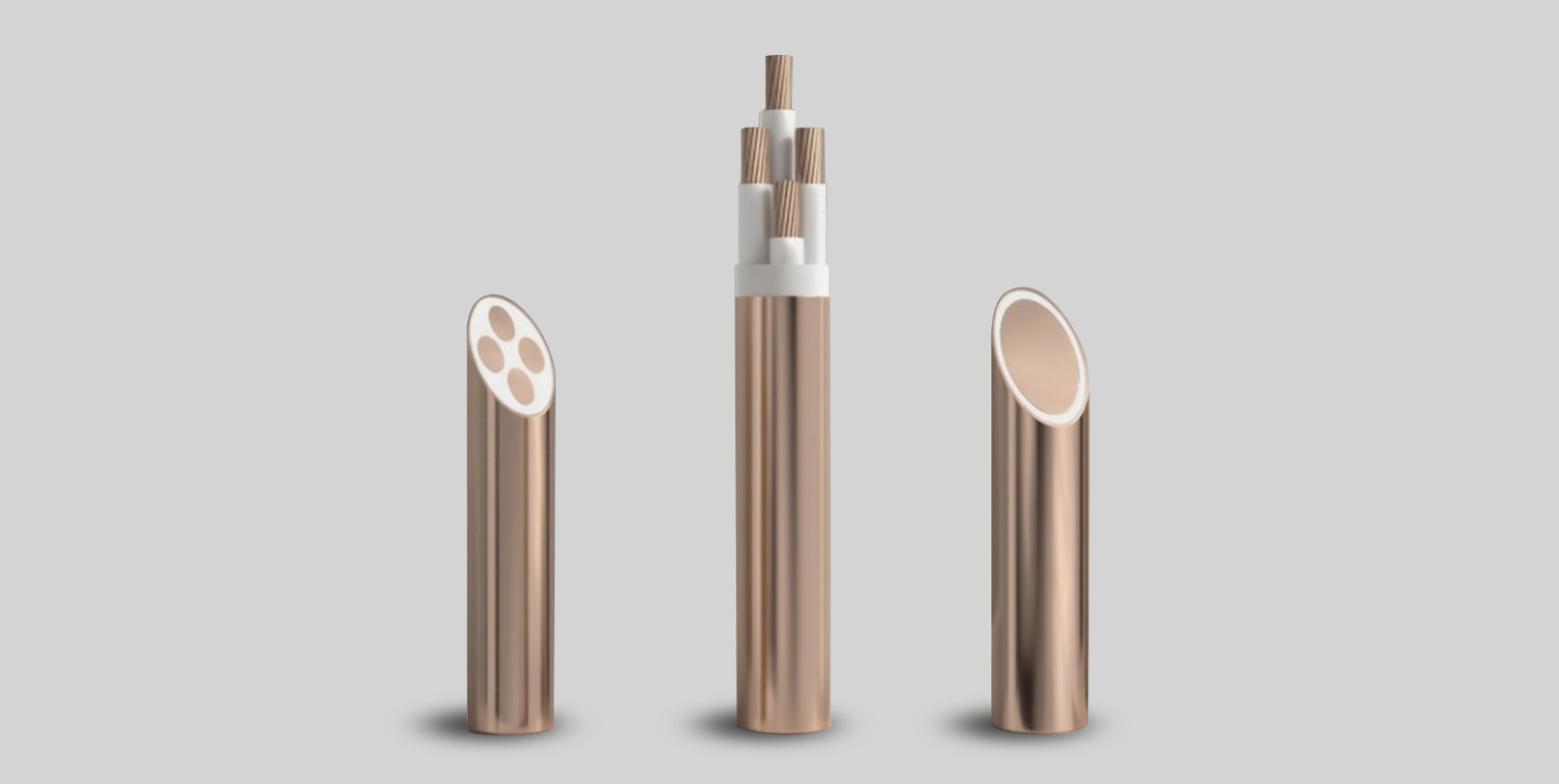

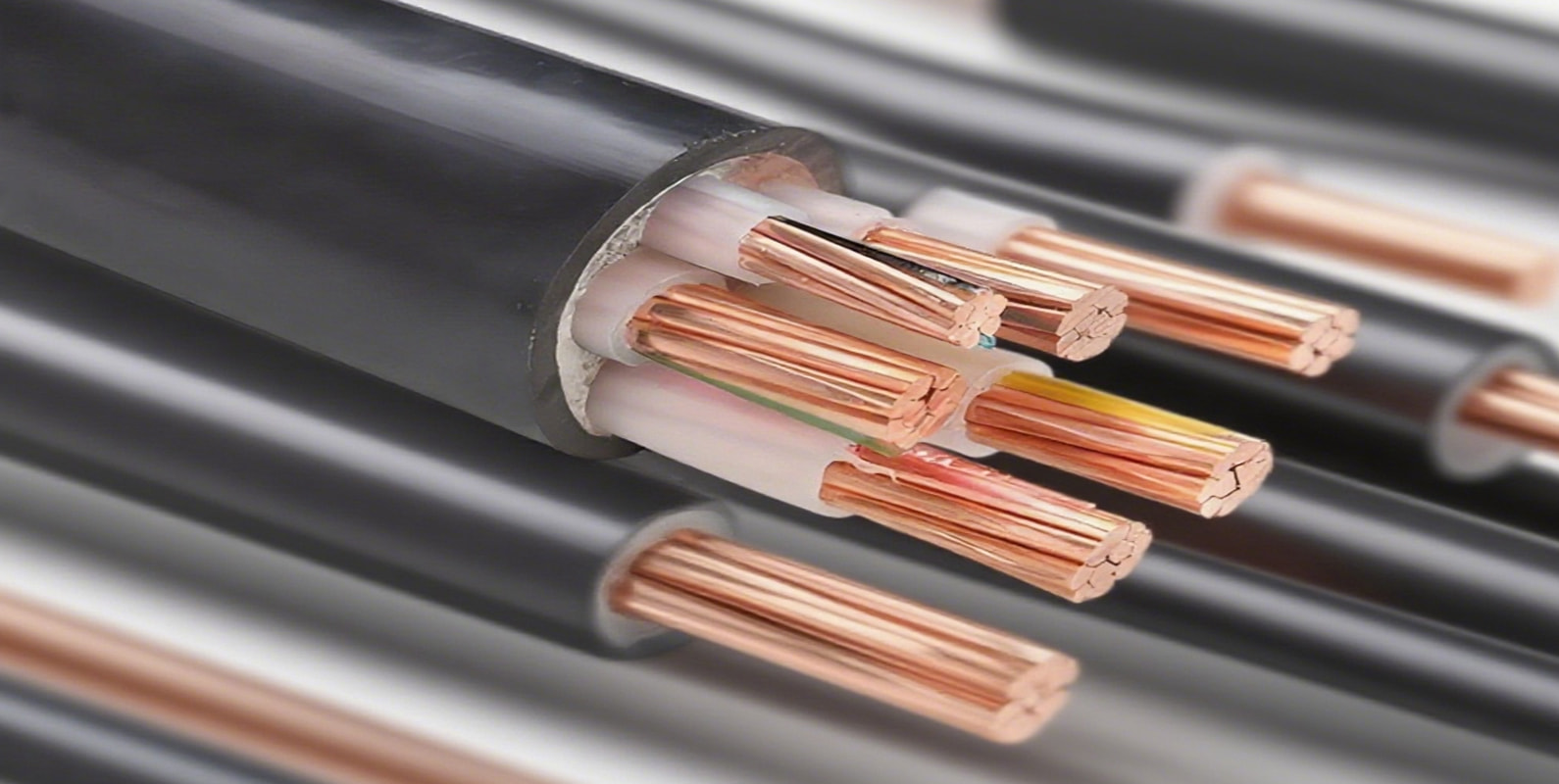

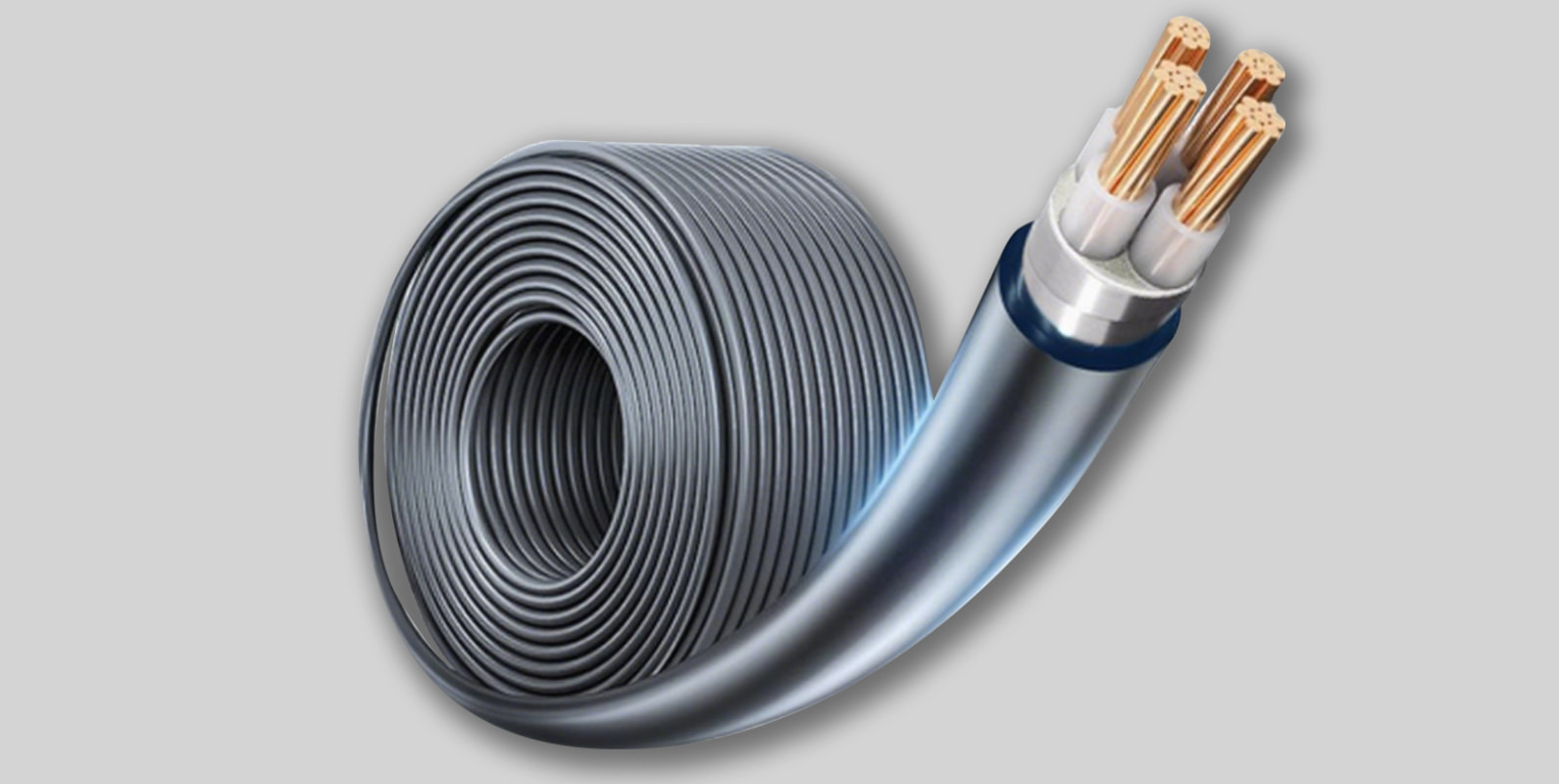

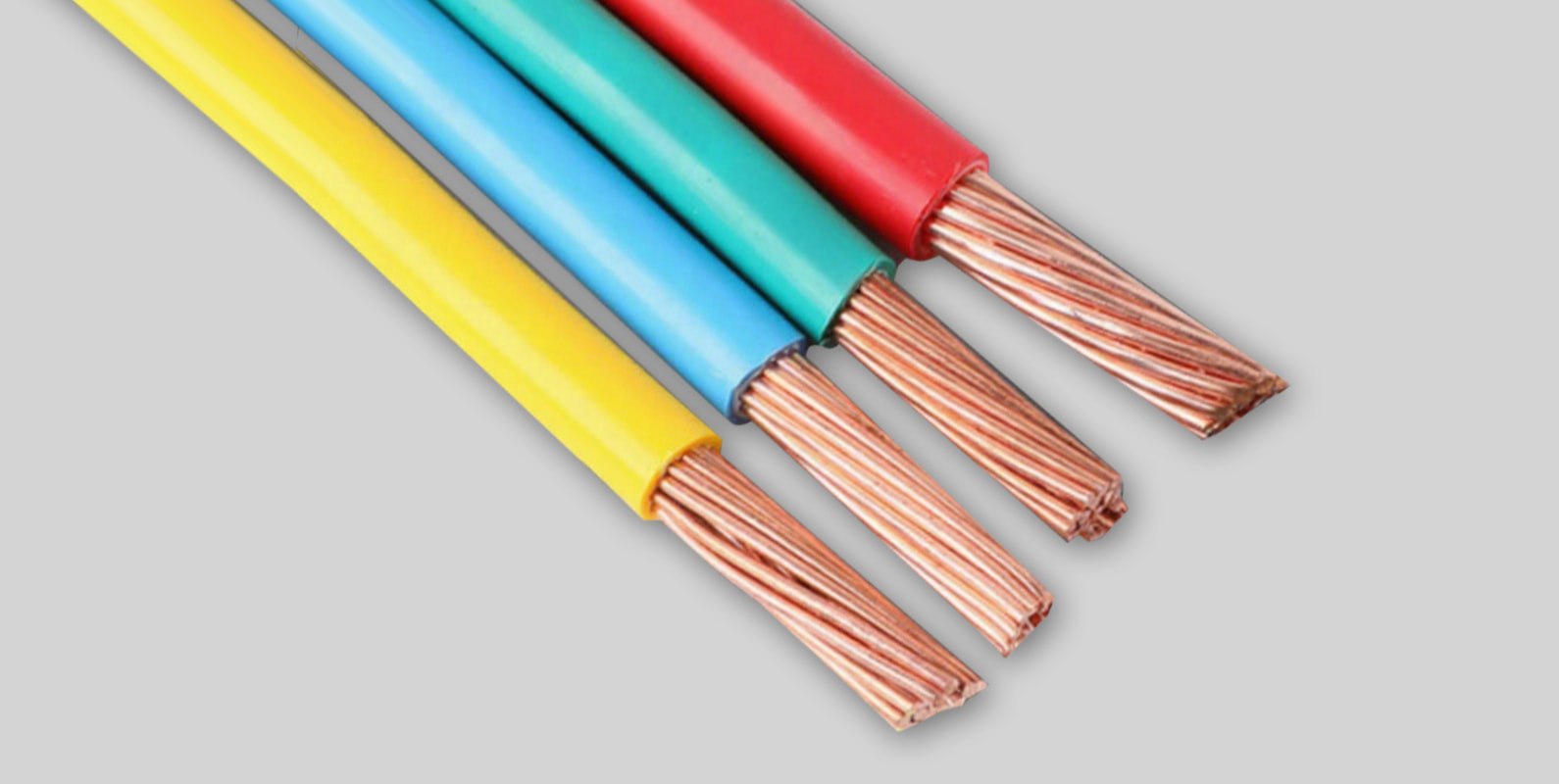

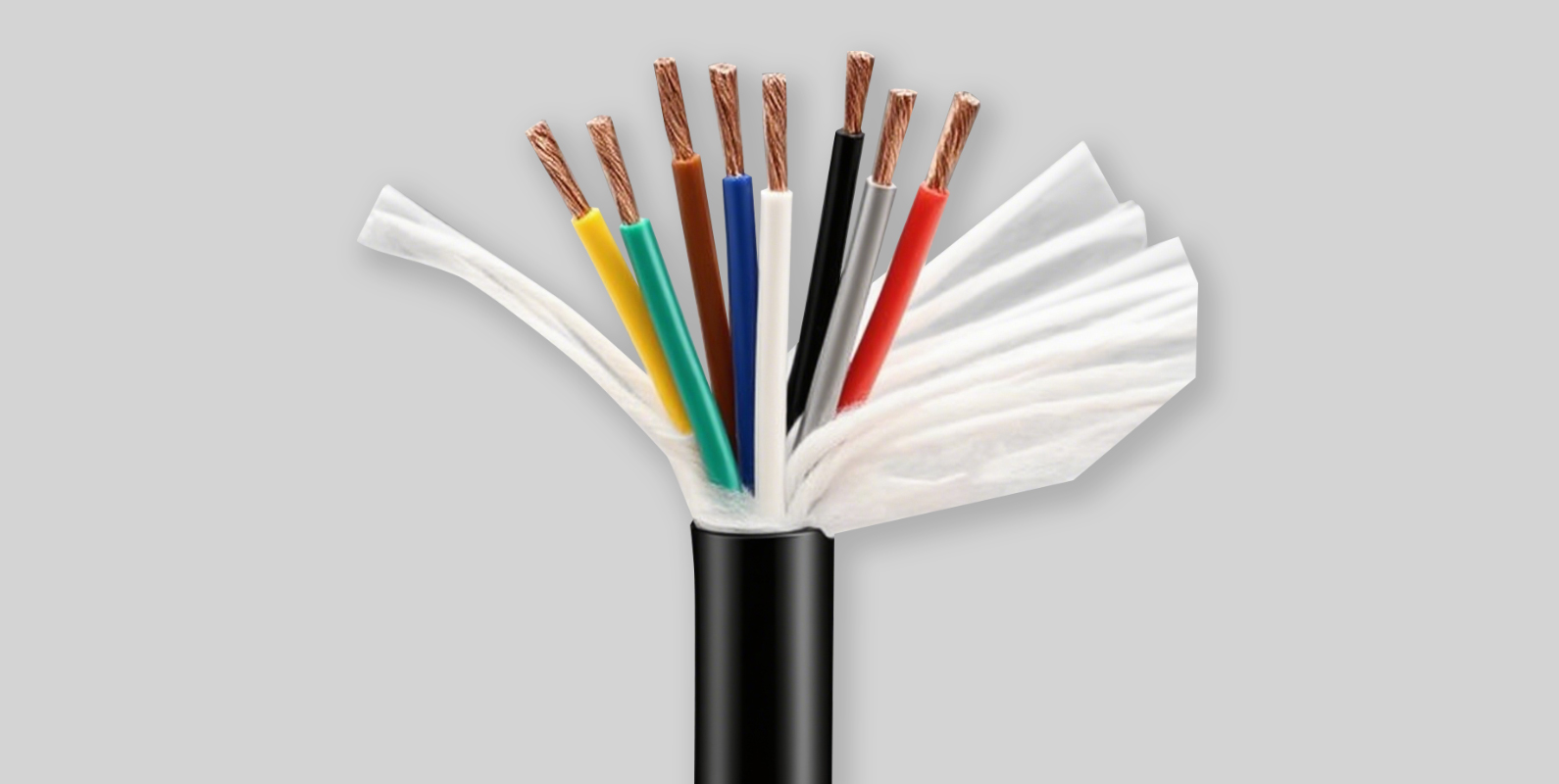

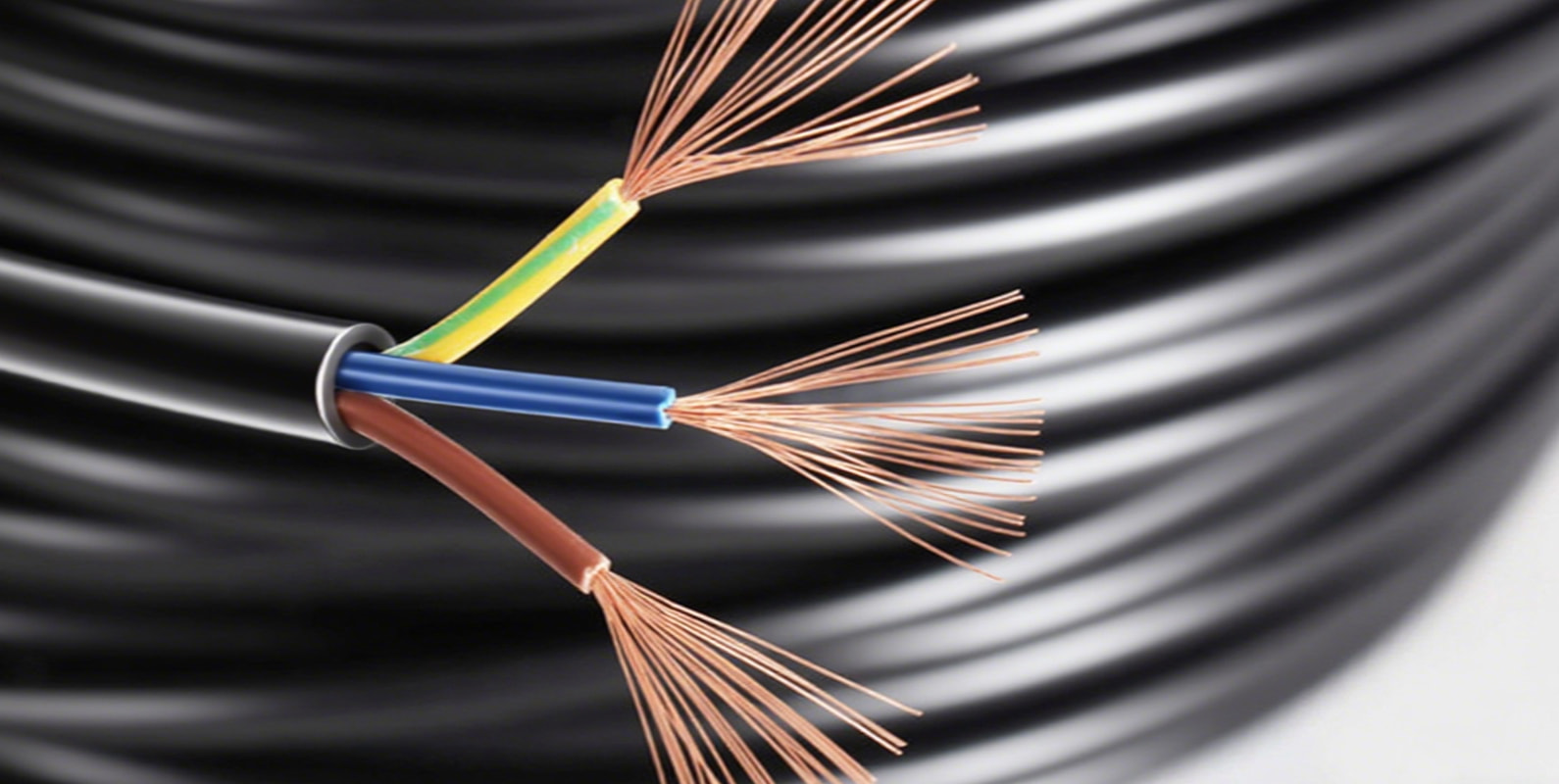

As the foundational veins of today’s interconnected world, wire and cable products are built on strength, durability, and precision. Engineered with advanced insulation materials and shielding technologies, they are designed to withstand bad temperatures, humidity, and mechanical stress—ensuring stable and secure transmission of power, signals, and data across industries. Applications span residential electricity supply (appliances, lighting, and communication networks), commercial buildings (security systems, elevators, HVAC, and data infrastructure), industrial and transportation sectors (automotive and aerospace power/signal delivery under harsh conditions), as well as the telecommunications industry (fiber-optic high-speed long-distance data transmission) and renewable energy systems (solar cables for photovoltaic connections). Key advantages include multifunctionality, compliance with international safety standards, and flexible customization. Flame-retardant, low-smoke halogen-free, and armored variants are available to meet specific environmental and engineering needs—making wire and cable systems the nervous system of modern infrastructure.

中文简体

中文简体 English

English